Products

1.Pyrolysis oil:

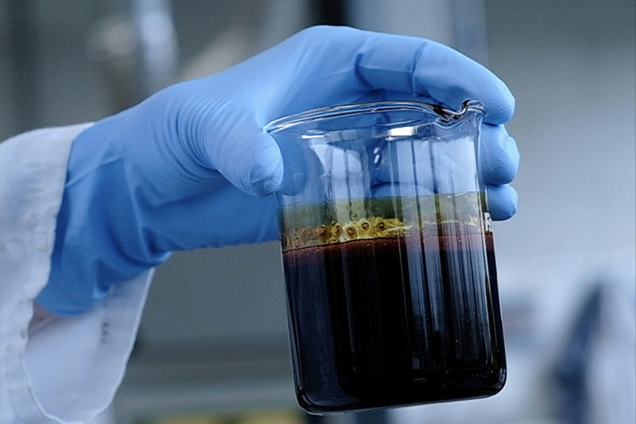

Pyrolysis oil, also known as bio-oil, is a synthetic fuel derived from the thermal decomposition of organic materials in the absence of oxygen. This process, known as pyrolysis, involves heating biomass, plastic, or rubber materials to high temperatures, resulting in the breakdown of complex organic compounds into simpler hydrocarbons. Pyrolysis oil can be refined to produce various valuable fuels, including diesel, fuel oil, and furnace oil. Here's our main products in PLASTOIL:

Pyrolysis Diesel:

- Pyrolysis diesel is a type of renewable diesel fuel produced through the pyrolysis process.

- It shares similarities with traditional diesel fuel and can be used as a drop-in replacement in diesel engines without significant modifications.

- Pyrolysis diesel is considered a sustainable alternative to conventional diesel because it is derived from renewable resources such as biomass or waste plastics.

Pyrolysis Fuel Oil:

- Pyrolysis fuel oil is a product of the pyrolysis process and is often used as a substitute for traditional fuel oils derived from fossil fuels.

- It is commonly used in industrial applications, including heating boilers and furnaces, due to its relatively high energy content.

- Pyrolysis fuel oil can be a viable option for industries looking to reduce their reliance on conventional fossil fuels and lower their carbon footprint..

Pyrolysis Furnace Oil:

- Pyrolysis furnace oil is another variant of pyrolysis oil specifically designed for use in furnaces.

- It can be utilized in various heating applications, including industrial furnaces and boilers.

- The properties of pyrolysis furnace oil may vary based on the feedstock and pyrolysis conditions, and it is essential to ensure compatibility with the intended combustion system.

Advantages:

- Pyrolysis oil is derived from waste materials, providing a sustainable and environmentally friendly alternative to traditional fossil fuels.

- The use of pyrolysis oil contributes to reducing greenhouse gas emissions, as it is often produced from organic waste materials that would otherwise contribute to environmental pollution.

- Pyrolysis oil allows for the recovery of energy from non-recyclable plastics and other waste materials, contributing to a more circular and sustainable economy.

2.Carbon Black:

PLASTOIL offers expertise in environmental consulting, working closely with clients to implement effective waste management strategies and sustainable solutions tailored to their specific needs.

Properties of Carbon Black:

1.Appearance:

Carbon black is typically a fine black powder.

2.Composition:

It is primarily composed of elemental carbon, and its properties can vary depending on the type of plastic feedstock and the pyrolysis conditions.

3.Surface Area:

Carbon black often has a high surface area, which makes it useful in various applications.

Applications of Carbon Black from Plastic Pyrolysis:

1. Reinforcing Agent in Rubber Products:Carbon black is commonly used as a reinforcing filler in the production of rubber products, such as tires. It enhances the mechanical properties, durability, and wear resistance of rubber compounds.

2. Ink and Paint Production:Carbon black is used as a pigment in the production of inks and paints due to its black color and fine particle size.

3. Battery Electrodes: In some cases, carbon black is used as a component in the production of battery electrodes, where its conductivity properties are beneficial.

4. Construction Materials: Carbon black can be incorporated into construction materials, such as concrete and asphalt, to improve their mechanical properties.

5. Water Filtration: The high surface area of carbon black makes it suitable for water filtration applications, where it can adsorb impurities.